-

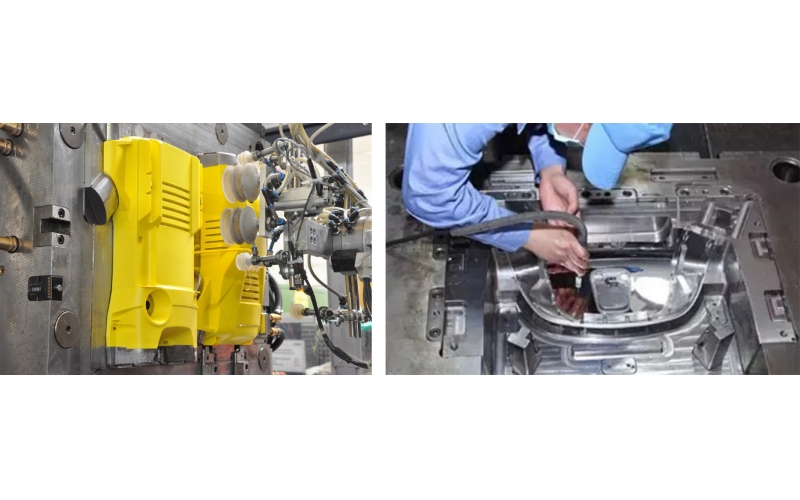

Injection mold maintenance skills

Good maintenance of injection molds can extend their service life, improve production efficiency, and enhance product quality.I. Maintenance before ProductionInspect the Appearance of the MoldCarefull

2024/10/12 maintenance skills

-

Advantages and disadvantages of acrylic/Plexiglass /PMMA material?

PMMA is short for polymethyl methacrylate, also known as acrylic or plexiglass, it is widely used, suitable for injection molding extrusion and other processes, its advantages and disadvantages are as

2024/08/03 PMMA

-

Advantages and disadvantages of EVA materials

EVA (ethylene-vinyl acetate copolymer) material is a common plastic material with good flexibility and transparency. It is usually used in the middle sole of shoes, sports MATS, toys, handbags, packag

2024/03/19 EVA

-

Advantages and disadvantages of ASA materials

ASA (styrene acrylic acrylate) is a thermoplastic with special properties and is often used in applications that require good weather resistance and mechanical properties. Here are some advantages and

2024/03/19 ASA

-

Advantages and disadvantages of TPEE materials

TPEE (thermoplastic polyester elastomer) is a material between rubber and plastic that has both the processing properties of plastic and the physical properties of rubber. The following are the advant

2024/03/05 TPEE

-

Advantages and disadvantages of PLA plastics

PLA, full name Polylactic Acid, is a biodegradable thermoplastic polyester. It is derived from renewable resources (such as cornstarch, sugar cane), which is both environmentally friendly and in line

2024/02/29 PLA plastics

-

Advantages and disadvantages of UHMWPE ultra-high molecular weight polyethylene

UHMW Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic polymer with very high molecular weight. The molecular weight of UHMWPE is generally in the range of millions to tens of milli

2024/02/28 UHMWPE

-

The difference between TPE and TPR materials

The terms TPE (thermoplastic elastomer) and TPR (thermoplastic rubber) are sometimes used interchangeably, but usually they represent the same class of materials or a closely related family of materia

2024/02/25 TPE and TPR materials