Advantages and disadvantages of PFA materials

PFA plastic, also known as meltable polytetrafluoroethylene, a small amount of perfluoropropyl perfluorovinyl ether and

polytetrafluoroethylene copolymer, is a high performance engineering plastic, with the following advantages:

1, excellent high temperature resistance: has very high thermal stability, can work in a high temperature environment for

a long time without deformation or decomposition, long-term use temperature of -80 ℃ ~ 260℃, short-term even up to

300℃ or more.

2, excellent corrosion resistance: It has good corrosion resistance to most chemicals and solvents, including strong acids,

strong alkalis and organic solvents.

3, good mechanical properties: with high strength and stiffness, can withstand a certain amount of pressure and impact,

its creep resistance and compressive strength are better than polytetrafluoroethylene, high tensile strength, elongation up to

100% ~ 300%.

4, low friction coefficient: the inner surface is smooth, low friction coefficient, can reduce the resistance loss during fluid

transmission, improve the efficiency of the system.

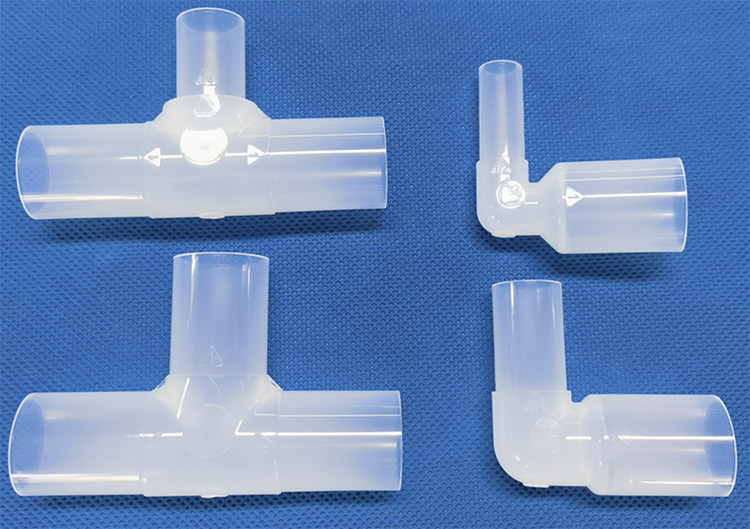

5, easy processing and installation: with good plasticity and processing properties, can be made into various shapes and

sizes of products through injection molding, extrusion and other processes. In addition, PFA connectors usually adopt

standardized connection methods, such as flanges, threads, etc., which is convenient and quick to install.

6, good electrical insulation: its electrical insulation is not affected by temperature, and it has good dielectric properties.

7, physiological inertia: can be implanted in the human body.

However, PFA materials also have some disadvantages:

1, high cost: due to the complex production process and the high cost of raw materials, the price of its products is relatively

high, which limits its application in some cost-sensitive fields to a certain extent.

2, limited corrosion resistance to specific media: although there is good corrosion resistance to most chemicals and solvents,

there may be corrosion or swelling in some specific media (such as some halogenated hydrocarbons, aromatic hydrocarbons, etc.).

3, long-term use may have aging problems: although PFA materials can maintain good performance in most environments,

but in some extreme climatic conditions, such as long-term exposure to ultraviolet light, its performance may be affected.

4, injection molding is difficult: poor fluidity, easy to decompose, decomposition of corrosive gas, should strictly control the

molding temperature should not exceed 475℃, the mold should be heated to 150-200℃, the gating system on the material

flow resistance should be small; And because the molten material has a corrosive effect on the metal, long-term production,

the mold needs to be electroplated chromium treatment.

When selecting PFA materials, it is necessary to consider their advantages and disadvantages as well as the requirements of

actual application scenarios to ensure that they can meet the requirements of long-term stable operation.